- Pitch Reviews

- Posts

- The Future of On-Demand Manufacturing

The Future of On-Demand Manufacturing

Plus, TechCrunch's Alex Wilhelm on the Pod talking top Tech founders of all-time.

Heyyyo,

It’s no secret Chicago startups have been on fire of late — from Cameo, M1 Finance, G2, ActiveCampaign, ShipBob (all officially reaching 🦄 status) to Meet With Spot, Hologram and Songfinch. This recent TechCrunch article breaks down exactly how well Chicago’s tech/startup scene stacks up against other booming tech hubs… So, naturally I invited one of the reporters (and host of Equity Podcast), Alex Wilhelm on the pod to catch up… And, before long, we had built an entire pantheon of all-time tech founders; past, present and future.

This pod is a absolutely loaded!

Here’s my full interview with @Alex:

Follow me on Twitter @kitun.

Scott

Every week I breakdown startup pitches with the added hook that you can invest whether you’re accredited or not (if you don't know what that means, click here).

👇 If you like what you see here and haven’t already subscribed, please do 👇

Company Bio

Accelerate3D uses its patented 3D printing machines to make exciting new products faster and cheaper than ever before.

Accelerate3D is very much like an outsourced R&D shop for manufacturers looking to more efficiently prototype and develop new products via high-speed 3D printing. If you think about it, 3D printing has been lurking in the background for years. But, manufacturers have been somewhat slow to adopt the new tech for a myriad of reasons — many of which Accelerate3D resolves by offering design and execution services that enable manufactures to save money and time on low volume orders rather than fumbling around internally trying to implement entirely new systems.

Meet the Founder

Watch my full interview with Accelerate3D Founder Riley Knox here.

Riley invented Accelerate3D’s core patent pending 3D printer design and built the proof of concept prototype in his garage. Prior to Accelerate3D, Riley spent 5 years working in the 3D printing space, with over a decade of experience with prototype design and fabrication.

Riley is a really smart designer who is the definition of a garage builder. He’s spent his entire career building and perfecting the process of high speed 3D printing so it’s no surprise he decided to build a business around his invention. The question becomes, how successful can he and the team be a growing adoption. And, for what its worth they’ve been accepted into several high level accelerators and pilot programs which should assist in addressing those concerns.

Traction

Patented large-size, high-speed 3D printers forging a new future for on-demand manufacturing

Selected for the exclusive STANLEY + Techstars global accelerator program

Rave reviews from pilot customers, incl. Braden Reiber, CEO/Founder of REMUV (working with Airgility).

Explosive 3D Printing Industry Growth—upwards of $120B by 2025

Like many of the medtech and robotics companies I’ve reviewed, Accelerate3D is more or less in pilot mode with a relatively untested revenue model — which is to be expected. As far as opportunity, the TAM is quite large and the inevitability of 3D printing being more widespread is clear. They’ve got several live pilot projects with large manufacturers so if any of those pilots turn into meaningful orders Accelerate3D is well on its way to proving its value at scale.

Terms & Takeaway

Invest in Accelerate3D here 👉 Term Sheet

Security Type: Reg CF

Pre-Money Valuation: $6,000,000

Investment Goal: $1,070,000

Raised (as of publishing): $190,563

Minimum Investment: $100.00

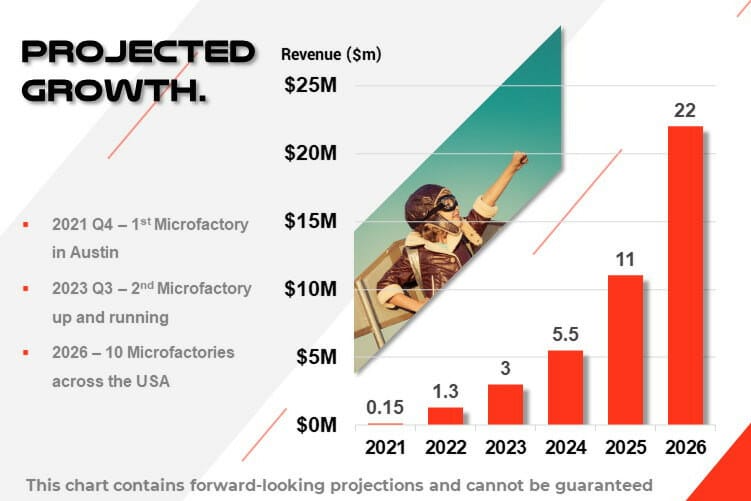

Here's what I like: I think Riley is very bright and the product appears to offer some unique values to manufacturers large and small. I really like their ability to more quickly prototype and I am a big believer in micro-factories. You’re already seeing auto and aerospace companies like Tesla and SpaceX utilize rapid development technology and processes like Accelerate3D to build smaller components for vehicles.

Here's what I don't love: Manufacturers are slow as molasses. My big fear would be that they cannot afford to wait as long as it may take for manufacturers to come around to modern practices. Additionally, it requires some experience with the technology to fully grasp its potential.

Who should invest and why: The price of a $6m convertible is more than fair given the assets already developed and early interest. If you’re a Gearhead or have spent any time in manufacturing Accelerate3D is worth a look as the tech and process is incredible. I personally, believe that micro-manufacturing is going to be an integral part of the product development process and its a matter of when, not if, it becomes a widely adopted by manufacturers.

As always, startup investing is super high risk, anything can happen.

Invest in Accelerate3D here 👉 Term Sheet

Questions? DM me on Twitter @kitun